The future of automation in food packaging and processing is here.

With technological advancements and a shift towards a more efficient and sustainable approach, automated systems are set to revolutionize the way food is packaged and processed.

From robotic arms that can handle delicate fruits to intelligent conveyor systems that streamline the packaging process, automation offers numerous benefits for both manufacturers and consumers. With increased accuracy and speed, automation reduces the risk of human error and ensures consistent quality. It also enhances food safety by minimizing the risk of contamination.

As the demand for packaged food continues to grow, automation will play a crucial role in meeting these demands while reducing costs and increasing productivity. With the development of smart machines and artificial intelligence, food packaging and processing will rely on engineered solutions more than ever.

Why Technology Matters in Food Processing Operations

As we look ahead to the next decade, emerging technologies like AI and Machine Learning (ML) will revolutionize the food processing industry. These advancements will have a significant impact on every aspect of operations, from production to distribution.

Here’s why this technology matters in the food industry:

- Increased efficiency: Automation, artificial intelligence, and robotics will streamline processes, reducing the need for more dangerous manual labor and increasing efficiency. This allows food processors to produce more with fewer resources and less risk, ultimately lowering costs and increasing productivity.

- Improved quality and safety: Technology enables precise control and monitoring of every step in the food processing operation. From temperature and humidity control to quality testing and traceability, new systems will ensure that food products meet the highest standards, reducing the risk of contamination and enhancing overall safety for workers and consumers.

- Enhanced sustainability: With the increasing need for sustainable and environmentally friendly practices, new technology will offer solutions to minimize or neutralize waste and optimize resource utilization. Sophisticated data analytics and machine learning help identify areas for improvement, allowing the food industry to minimize its environmental impact.

- Meeting changing consumer demands: Emerging technologies will enable food processors to adapt quickly to changing consumer preferences. From personalized nutrition to new packaging materials, technology allows for innovation and customization, ensuring that food products meet evolving customer needs.

Labor Market Considerations

In recent years, labor market considerations have significantly influenced the adoption of automation and new technology in food processing plants. Labor shortages, productivity optimizations, and overall operational efficiency are all driving factors here.

One of the primary reasons why the food industry is turning to automation and technology is the scarcity of skilled labor in the industry. With a limited pool of qualified workers available, companies are exploring innovative solutions to fill the gaps and maintain a competitive edge. By implementing advanced technologies such as robotics, artificial intelligence, and machine learning, these processors are able to streamline their operations and accomplish tasks that would otherwise require a larger workforce.

Machines will not replace your human workforce any time soon. Fortunately, the adoption of better technology has proven to attract better workers. Skilled candidates are often drawn to companies that prioritize innovation and safety. By demonstrating a commitment to staying ahead of the curve, food processors can not only attract top talent but also retain their best employees.

There is an essential balance between technology and human laborers. While automation and technology can increase efficiency, they cannot replace the critical thinking and adaptability of human workers. Technology augments human capabilities rather than eliminates the need for human labor altogether. Collaborative efforts between machines and workers can lead to optimal results, with workers focusing on tasks that require human judgment and problem-solving skills. This helps optimize your labor costs.

Ultimately, the goal is not to replace the workforce with machines but to enhance it. By leveraging automation and technology, food processors can create a workforce that is more efficient, productive, and adaptable to changing market dynamics.

Worker Safety Considerations

One key advantage of robotics and automation for food manufacturers is the minimization of human interaction with potentially hazardous materials and processes. This not only safeguards the physical well-being of your workers but also protects them from long-term health hazards – and reduces the risk of injury and worker’s compensation claims to your business.

The precision and consistency offered by robotic systems result in fewer errors and, consequently, fewer injuries. These machines are programmed to adhere to strict safety protocols, reducing the chances of equipment malfunctions, cuts, slips, trips, and falls. Additionally, automated material handling equipment eliminates the need for manual lifting and carrying of heavy loads, reducing the risk of musculoskeletal injuries.

Food Safety Considerations

Food safety is a top priority for any food processing plant. With the advancements in robotics, AI (Artificial Intelligence), machine learning, and automated quality control equipment, ensuring the safety of food products has become even more efficient and reliable.

Robots and engineered solutions can play a vital role in food safety by handling tasks that involve contact with food, reducing the risk of contamination from human handling. They can accurately and consistently perform tasks like picking and packing, reducing the chances of errors or cross-contamination.

AI and machine learning algorithms analyze vast amounts of data to detect potential risks or deviations from the norm, allowing for real-time monitoring and prompt action. These technologies can assess sensory characteristics, such as color, texture, and odor, to identify any irregularities that may indicate spoilage or contamination.

Automation technologies for quality control equipment, such as photosystems, X-ray machines, and metal detectors, can quickly identify foreign objects, like metal fragments or stones, that may have accidentally entered the food production process. This automated inspection process enhances the safety and integrity of the final product.

Automation Trends in Food Processing & Packaging

From robotic food preparation to automated inventory management, technology is streamlining processes, enhancing quality, and improving customer experiences.

These are the top trending advancements and their biggest benefits to your bottom line:

Robotics and Assisted or Automated Material Handling

Robotics and automated material handling systems bring numerous benefits to food processing plants. By incorporating these advanced technologies, food processing plants can enhance their operations and improve overall efficiency. Here are some key advantages:

- Increased productivity: Robots and automated systems can handle repetitive and time-consuming tasks, allowing human workers to focus on more complex and value-added activities.

- Improved accuracy and precision: Automated systems can more accurately measure, sort, and package various food products, ensuring consistency in quality and reducing waste.

- Enhanced food safety: Automated material handling systems can help minimize the risk of contamination and cross-contamination by reducing human contact with food products.

- Cost savings: Improved efficiency, reduced labor requirements, and minimized wastage all contribute to significant cost savings over time.

- Flexibility and scalability: Advanced robotics and automated systems can be custom-built or tailored to meet the specific needs of a food processing plant. They offer the flexibility to handle various types and sizes of food products, allowing for scalability and adaptability as business demands change.

AI/ML and Analytics

As a food processing plant, incorporating AI, Machine Learning (ML), and automated analytics into your operations can bring numerous benefits. Here are some key advantages these technologies offer:

- Enhanced efficiency: AI and ML algorithms can analyze vast amounts of data in real time, helping to streamline production processes and optimize resource utilization.

- Improved product quality: With automated analytics, you can accurately monitor and control various variables such as temperature, humidity, and ingredient proportions. This ensures consistent product quality and reduces the risk of defects or deviation from desired specifications.

- Predictive maintenance: AI-powered systems can analyze sensor data from machinery and equipment to identify patterns and predict maintenance needs. By addressing potential issues proactively, you can minimize downtime, extend equipment lifespan, and avoid costly disruptions to your production line.

- Enhanced food safety: AI and ML algorithms can identify potential risks in the supply chain, such as contamination or counterfeit ingredients, ensuring the safety and integrity of your food products. Automated analytics also facilitate quick and accurate traceability, helping you swiftly identify the source of any issues.

- Decision support: AI and ML analytics generate valuable insights by analyzing data from multiple sources. These insights can inform decision-making processes, such as identifying market trends, optimizing pricing strategies, or improving demand forecasting.

How Automation & Technology Can Help You Hit Your ESG Targets

Automation and technology will play a vital role in helping food processing and packaging companies achieve their Environmental, Social, and Governance (ESG) targets. By embracing automation and digitalization, companies can not only enhance their operations but also positively impact various aspects of their business.

One key advantage of automation is its ability to address labor challenges. With an increasing shortage of skilled workers in the industry, automation can help companies overcome these challenges by automating repetitive and physically demanding tasks, allowing employees to focus on more value-added activities.

Additionally, automation can lead to cultural improvement within the organization. By implementing advanced technology and digital tools, companies can foster a culture of innovation, collaboration, and continuous improvement. This helps create a positive work environment and boosts employee engagement and satisfaction.

Utilizing automation and technology also enables companies to increase wages for their workforce. By automating certain tasks, companies can achieve greater efficiency, reduce costs, and allocate some of those savings toward providing higher wages for employees.

Automation helps in worker retention, too. By reducing the physical strain and monotony associated with certain tasks, employees are more likely to stay in their roles for a longer time. This leads to a more stable workforce and ultimately reduces the company’s turnover costs.

In terms of machine optimization, automation enables real-time monitoring and data-driven decision-making. By leveraging technology, companies can collect and analyze data to identify areas with potential performance improvements, optimize machine settings, and minimize downtime, ultimately increasing overall productivity.

Lastly, automation and technology can significantly contribute to sustainability efforts. By eliminating waste, reducing energy consumption, and improving accuracy, companies can enhance their environmental footprint. For example, automation can help minimize food waste, optimize packaging materials, and streamline logistics, all of which contribute to a more sustainable operation.

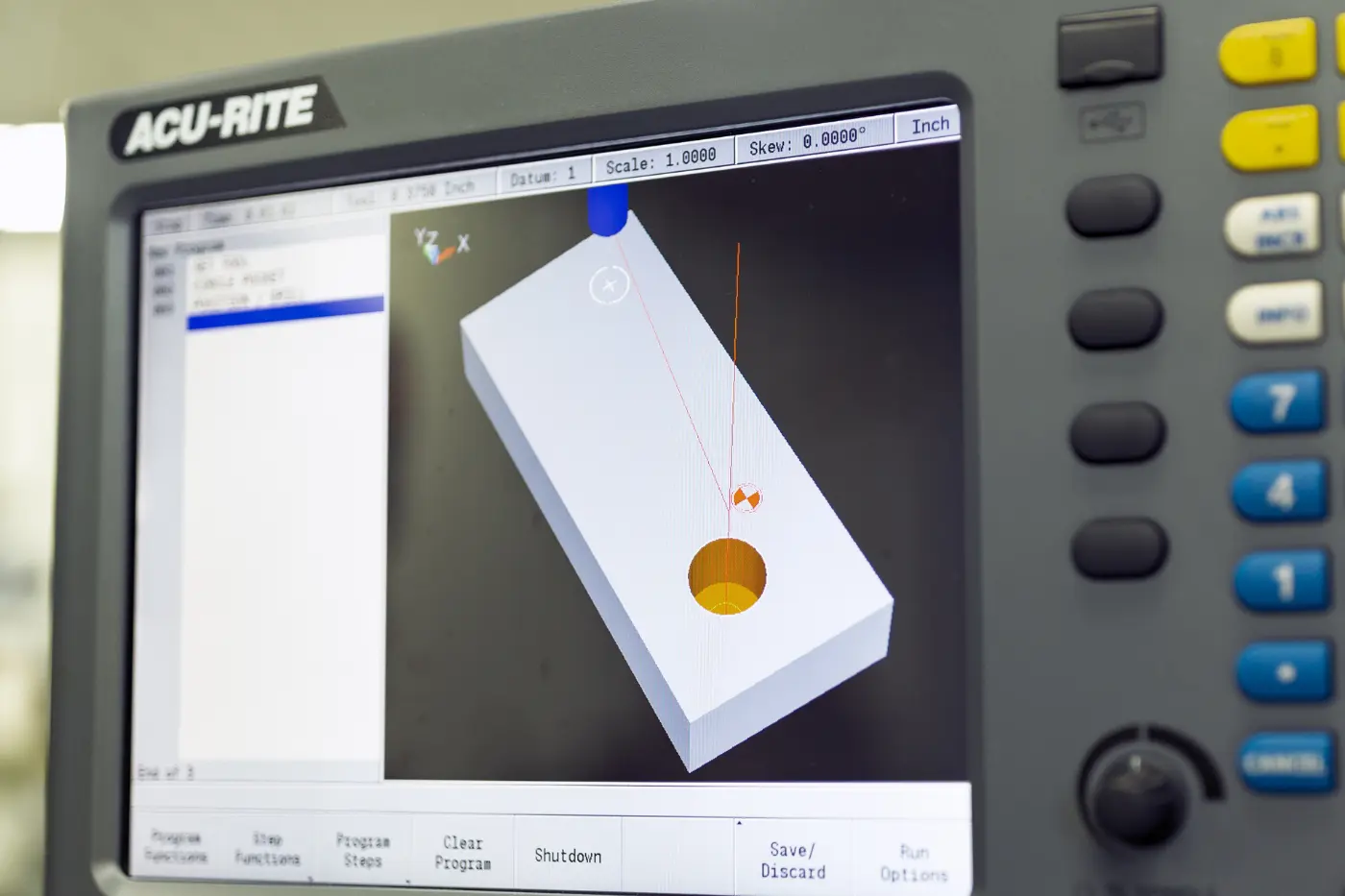

Custom-engineered Solutions Lead the Way

Custom-engineered automation solutions are paving the way for innovation and success in food processing and packaging. These bespoke solutions, which are tailored to meet specific needs and requirements, make automation possible for repetitive, inefficient, or dangerous processes. They enable businesses to address their unique challenges and maximize efficiency, ultimately driving growth and profitability.

With custom-engineered solutions, companies can optimize their operations, enhance productivity, and improve overall performance. These solutions offer flexibility and adaptability to changing circumstances, allowing businesses to stay ahead of the competition. See one such custom solution for meat packaging in this video showing a piece of custom equipment designed just for this customer.