Chainmail mesh PPE isn’t just another line item on a checklist—it’s critical gear for frontline safety in the meat and food processing industries. Built tough like medieval armor, this stainless-steel mesh stands up to cuts, punctures, and wear-and-tear that comes with the daily grind. But like any high-performance equipment, it only protects from work-related injuries as long as it’s properly maintained.

Understanding how chainmail mesh is built, spotting signs of damage before it becomes a potential hazard, and performing basic repairs in-house gives you more control over uptime and compliance. With the right tools and a little know-how, you can extend the life of your PPE and keep your team protected without delays or budget surprises.

How Chainmail Mesh PPE Is Built—and Why It Works

Chainmail might have medieval roots, but its design is anything but outdated. In the modern food industry, chainmail mesh PPE remains one of the most effective forms of cut-resistant protection available.

Chainmail is made from a dense weave of interlinked metal rings—usually stainless steel. This creates a tough, flexible mesh that deflects blades and sharp tools while allowing workers to move freely. That balance of strength and flexibility is what makes chainmail ideal for high-risk environments where precision and protection go hand-in-hand.

Each ring is carefully sized and fitted for a seamless finish. The tighter and more uniform the rings, the more consistent the protection, and the easier it is to spot wear or damage during inspections.

How to Spot Damage in Chainmail Mesh PPE Before It Becomes a Problem

Assessing the damage to chainmail mesh PPE is crucial to ensuring continued safety for your workers. Here’s how you can efficiently evaluate the condition of your protective equipment.

Start with a Surface Scan

Look closely at the mesh for broken, bent, or missing rings. Even a single weak spot in cut-resistant PPE can compromise worker safety. Frequent inspections catch these issues before they turn into preventable injuries.

Check for Wear and Thinning

Pay special attention to high-contact zones—palms, elbows, and midsection areas often wear down faster. If the mesh feels thin or uneven, it’s time to take action.

Inspect Seams and Stitching

In chainmail gloves and aprons, don’t overlook the stitching. If threads are fraying or seams are coming loose, that’s a sign the integrity of the PPE is at risk.

Watch for Discoloration

Rust or discoloration can indicate oxidation or chemical exposure. These weaken the steel and reduce protection. If your chainmail starts looking off-color, it’s a red flag.

Use the Right Light

Good lighting helps catch small flaws before they become big issues. Don’t skip this step—subtle damage is easier to miss than you think.

Why Routine Inspections of Chainmail Mesh PPE Aren’t Optional

When it comes to worker safety, chainmail mesh PPE is your first line of defense, and regular inspections are what keep that defense strong.

Over time, even the most durable protective gear wears down. Rings loosen. Seams weaken. Damage builds up quietly. Without a routine inspection process, small issues can go unnoticed until it’s too late—and that’s when injuries happen.

Protect Your People, Your Process, and Your Bottom Line

Routine checks help you catch problems early, like damaged rings or thinning mesh, before they compromise the integrity of your PPE. This kind of proactive maintenance isn’t just about staying compliant with safety standards; it’s about preventing injuries and avoiding costly disruptions to your operation.

Here’s what regular inspections help you do:

- Spot broken or loose rings before they fail

- Ensure PPE meets OSHA and industry safety standards

- Avoid emergency repairs and unplanned replacements

- Extend the lifespan of your cut-resistant gloves and gear

- Maintain a consistently safe work environment

The Payoff? Fewer Injuries, Lower Costs

Inspections take minutes. Injuries take people off the line and hit your productivity hard. Making routine PPE checks part of your standard operating procedure is one of the simplest, smartest ways to avoid potential hazards and protect your workforce and your ROI.

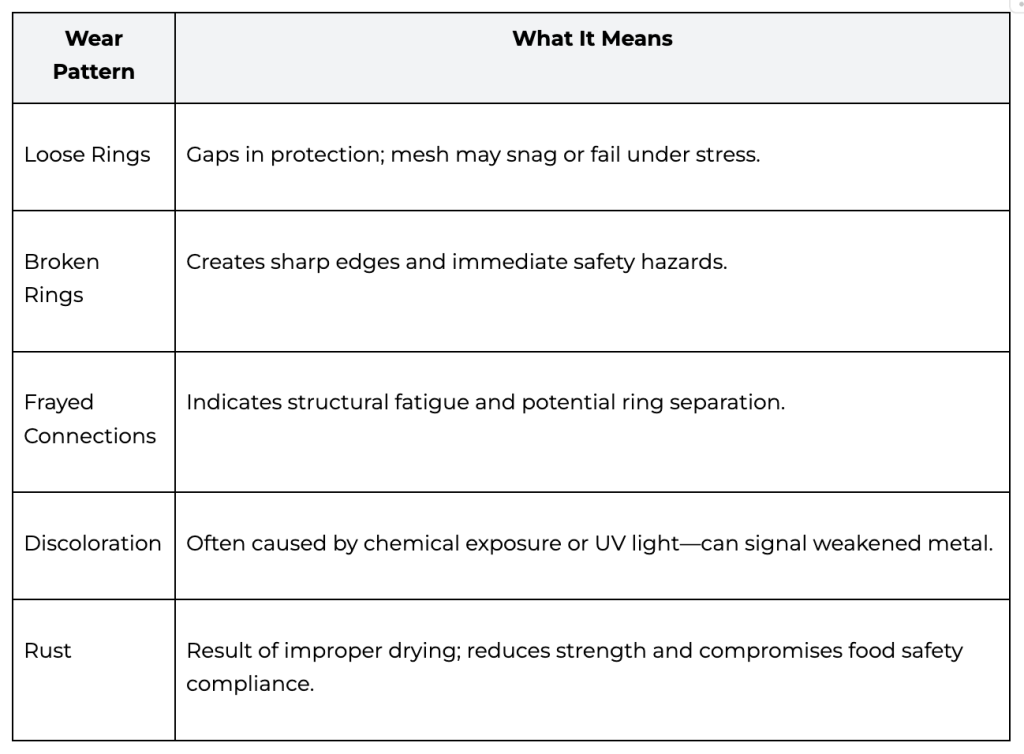

Common Wear Patterns in Chainmail Mesh PPE

Chainmail mesh PPE is built to take a beating. That’s what makes it so effective in food processing and other high-risk environments. But like any hardworking gear, it’s not immune to wear.

Where Chainmail Mesh Wears Down First

Certain areas of cut-resistant PPE take more abuse than others. Keep an eye on these hot spots:

- High-Flex Zones

In chainmail gloves, the areas where fingers bend or grip tools tend to wear down the fastest. Repeated movement weakens the mesh over time. - Mesh Connections

Points where rings meet or overlap can loosen as workers move. These stress points are common spots for failure. - Outer Edges and Seams

The border of aprons or sleeves is more likely to fray or stretch, leading to gaps in protection if not addressed.

Common Signs of Damage

Routine inspections should flag any of the following:

Tools and Materials You Need to Repair Chainmail Mesh PPE

Maintaining your chainmail mesh PPE isn’t just a best practice—it’s a non-negotiable when it comes to food processing safety. And like any task worth doing, it starts with having the right tools on hand to stay in compliance with industry standards.

Tools for the Job

- Needle-Nose Pliers

These allow you to open and close rings with accuracy. Choose a strong, fine-tipped pair for better control. - Wire Cutters

Necessary for removing damaged rings cleanly—don’t skip this step. - Replacement Stainless Steel Rings

Always use high-quality stainless steel rings that match your PPE. Low-grade metals won’t hold up under pressure.

Materials to Support the Process

- Mild Detergent & Warm Water

Clean the PPE thoroughly before repair. This clears away buildup and makes it easier to spot problem areas. - Protective Gloves

Even when working with protective equipment, your hands are at risk. Gloves help prevent accidental cuts during handling.

By having these tools and materials ready, you can extend the life of your cut-resistant PPE, reduce operational costs, and stay compliant with safety standards.

Repairing Chainmail Mesh PPE

Chainmail mesh PPE is a frontline defense in meat and food processing environments. It’s engineered to block cuts and punctures, but even the toughest gear wears down with time. When rings start loosening or breaking, prompt repairs are key to protecting workers and keeping your operation compliant.

How to Repair Chainmail Mesh PPE

- Inspect the Mesh

Start with a thorough inspection for signs of wear. Look for loose, broken, or missing rings—especially in high-movement zones like fingers, elbows, and apron edges. - Gather Your Tools

You’ll need:- Needle-nose pliers

- Replacement stainless steel rings

- Wire cutters (optional, for removing damaged rings)

- Remove Damaged Rings

Use pliers to gently open and extract any broken or misshapen rings. Be careful not to stretch or distort surrounding rings. - Insert New Rings

Link the replacement ring through the correct openings, following the original mesh pattern to maintain strength and flexibility. - Close the Rings Securely

Press the new rings closed tightly using pliers. Double-check the tension—loose closures compromise protection. - Final Check

Scan your repair zone. All rings should be secure, evenly aligned, and free of sharp edges.

Maintenance Tips to Prevent Future Repairs

- Clean regularly using warm water and mild detergent—never use bleach or harsh chemicals.

- Dry thoroughly before storing to prevent rust; avoid direct sunlight

- Inspect often to catch wear early and reduce long-term damage

Regular maintenance and timely repairs of your chainmail can reduce the risk of cuts and potential injury, ensuring continued safety for employees.

When to Call in the Pros

For extensive damage or large-scale repairs, International Services, LLC (ISL) has you covered. As the only Authorized Niroflex Repair Center in the U.S., we provide expert repair services that restore your chainmail PPE to factory standards—so your people stay safe and your plant stays productive.

Repair or Replace? How to Make the Right Call for Chainmail Mesh PPE

Chainmail mesh PPE is built tough, but even stainless steel has limits. Knowing when to repair and when to replace your gear isn’t just about saving money—it’s about keeping your team safe and your operation running without risk. Striking the right balance ensures that you keep costs down and maintain the level of protection required.

When to Repair

Minor damage—like a few broken rings or a loose seam—is usually an easy fix with the right tools and replacement parts. If the structure is otherwise intact, repairs can safely extend the life of your PPE and reduce unnecessary costs.

Best for:

- Light to moderate wear

- Recently inspected or newer gear

- Non-critical zones on gloves or aprons

When to Replace

There’s a tipping point where continued repair no longer makes sense, especially when it compromises protection. If large sections are worn, repairs don’t hold, or the mesh has been patched multiple times, replacement is the safer option.

Replace your chainmail PPE if:

- It’s no longer maintaining structural integrity

- The mesh is heavily discolored, rusted, or deformed

- It fails to meet safety compliance after repair

Know the True Cost of Compromise

Attempting to stretch the life of worn-out cut-resistant PPE may save dollars today, but could lead to costly injuries or shutdowns tomorrow. When in doubt, err on the side of safety.

Mixing professional repairs with timely replacements is key for ensuring worker safety. By maintaining high-quality chainmail, you’ll achieve the necessary protection level while keeping costs under control.

And if you’re not sure whether repair or replacement is best, ISL can help. As the only Authorized Niroflex Repair Center in the U.S., we can assess the condition of your gear and provide expert guidance, so you can protect your people without second-guessing your next move. Contact our International Services Team today.