About Fremont Automation

We Solve Problems Poultry Processors Don’t Know They Have.

Our History

From Hometown Innovation to Poultry Processing Automation.

Fremont Automation began with Dave Benes, a problem-solver who turned his farm-forged ingenuity into one of the Midwest’s most innovative engineering companies. From his first workshop in 1991, Dave led Fremont Automation from tool-and-die projects into the automotive industry, where the company built advanced manufacturing technologies for top OEMs. Guided by Dave’s belief in never building the same machine twice, the company grew a reputation for innovative automation solutions that solved complex challenges.

In the early 2000s, Fremont Automation became a true family business as Amanda Benes, now CEO, joined her father along with brothers Jacob and Ben. The Benes family expanded the company’s capabilities and shifted focus to food and poultry processing. This new direction allowed them to apply their expertise in chicken processing automation and commercial food processing equipment, building momentum for the next breakthrough.

That turning point came when Fremont Automation designed the first automated Saddlepack Taper.

This was soon followed by the Saddlepack Depositor, establishing Fremont as a pioneer in automated chicken packaging. Today, with customers from Costco to Butterball to Pilgrim’s Pride, Fremont Automation continues to deliver premier protein packaging and poultry packaging solutions.

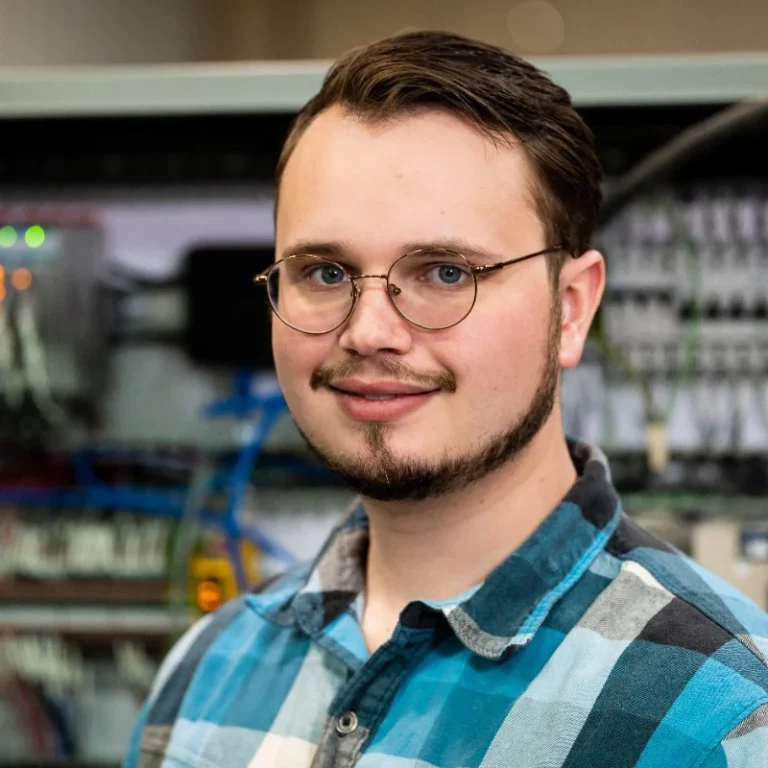

Leadership

Led by Family, Purpose, and Passion.

Real Results in Real Time

Saved one plant

$5M

per year

Does the work of

4-6

people per line

Under

1

year to reach ROI

Nationwide Installation

Built in the Midwest.

Working Everywhere Poultry Is Processed.

Designed and built in the U.S.A., these hard-working automation solutions are being used by the top names in poultry processing. Our OEM agnostic equipment connects with upstream and downstream machines so you don’t have to redesign your line to get the benefits of automation.

Why Fremont

Why Fremont Automation?

We’ve Put Decades of Innovation Into Perfecting Poultry Packaging.

Built for

Poultry Plants

Our packaging automation equipment was designed for the realities of poultry processing — from slippery product to washdown requirements. While other options adapt generic packaging equipment, we’ve built solutions that actually work in your plant.

Engineers Who Stand

Behind Their Work

The engineers who design your equipment are the same ones who install and support it. Because they’re responsible for every stage — from build to training to service — they make sure it’s done right the first time.

Automation That

Doesn’t Quit

Built tough to run shift after shift, our equipment delivers reliable automation with less parts, less maintenance, and fewer costly interruptions.

American-Made,

Midwest Proud

Designed and built in the U.S.A. Our team takes pride in delivering hometown innovation and hard-working solutions with the craftsmanship you demand.

Long-Term Partnership

and Support

ROI in

Under a Year

Reduce maintenance, parts, and labor costs. Most equipment pays for itself in 12 months or less. Your investment delivers measurable savings and operational cost reductions that grow year after year.

Resources

Join Our Team

We are always looking for innovative thinkers to add to our team. If you are interested in working with us, send us your resume.

Frequently Asked Questions

What does Fremont Automation do?

Fremont Automation designs and manufactures packaging automation equipment for the food manufacturing industry, with a core focus on poultry processing. Our mission is to help poultry processors keep lines moving with automation that is fast, safe, and maximizes uptime.

We concept, design, fabricate, integrate, and program our own equipment, offering a true one-stop shop for poultry packaging automation. Our flagship products are the Saddlepack Depositor and Saddlepack Taper, which together address some of the most labor-intensive and challenging packaging tasks in chicken processing plants.

How does Fremont Automation improve chicken processing?

We address the biggest bottlenecks in poultry packaging by automating jobs that are hard to staff and prone to error:

- Reduce labor strain: Our machines typically cut the staff needed for a task from 4–6 people down to 2, helping plants overcome chronic labor shortages.

- Increase throughput and uptime: Built to run shift after shift, our automation eliminates downtime and bottlenecks with less maintenance and fewer costly interruptions.

- Stop packaging waste: The Saddlepack Depositor guides wet product all the way into the pouch to keep seal surfaces clean, preventing “leakers” and costly rework.

- Improve worker safety: We automate injury-prone tasks like taping and gluing with the Saddlepack Taper, reducing repetitive strain and freeing employees for higher-value work.

- Support sustainable packaging goals: Our equipment handles recyclable trays and pouches, making it easier to transition away from foam trays without slowing production.

What makes Fremont Automation different?

Fremont Automation stands apart in these key ways:

- Purpose-built for poultry: While others adapt generic packaging machines, our equipment is designed specifically for the realities of wet, variable poultry products and washdown environments.

- Engineers who stand behind their work: The same engineers who design our equipment also install and support it, ensuring reliability, serviceability, and seamless integration.

- Focus on uptime, not spare parts: We integrate technology to simplify maintenance and reduce spare part costs, such as using Linmot Servo Motors to cut 60 parts from our Taper design. We’re not in the spare parts business; we’re in the uptime business.

- Long-term partnership: We don’t just drop off machines. We provide ongoing support, free check-ins, and even help address upstream or downstream equipment issues to keep your entire line flowing.

Where is Fremont Automation located?

What experience does Fremont have in chicken processing automation?

With decades of industry expertise, we’ve engineered and installed automation solutions that deliver measurable ROI for the world’s leading poultry processors. We built the Depositor and Taper after larger firms said these processes “couldn’t be automated.” We solved the problem holistically — designing for the end result rather than trying to mimic human motion with robotics.